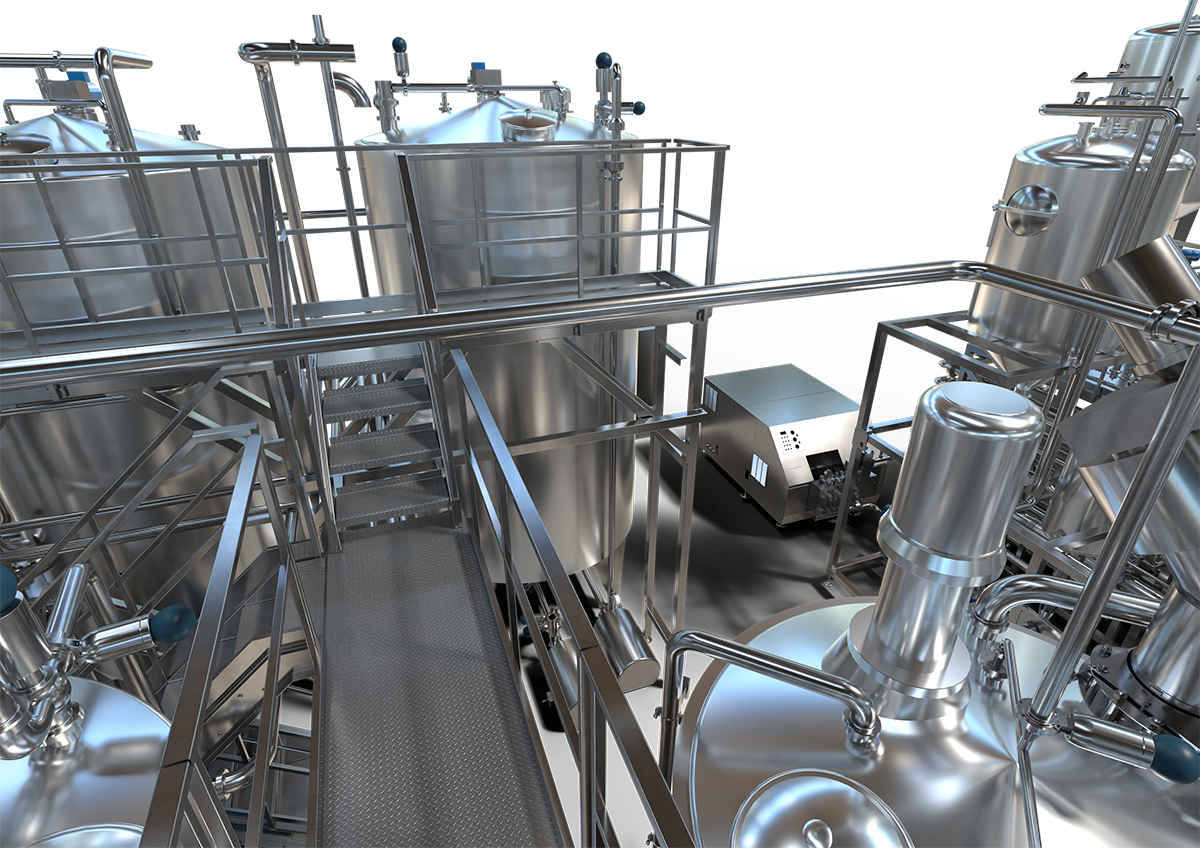

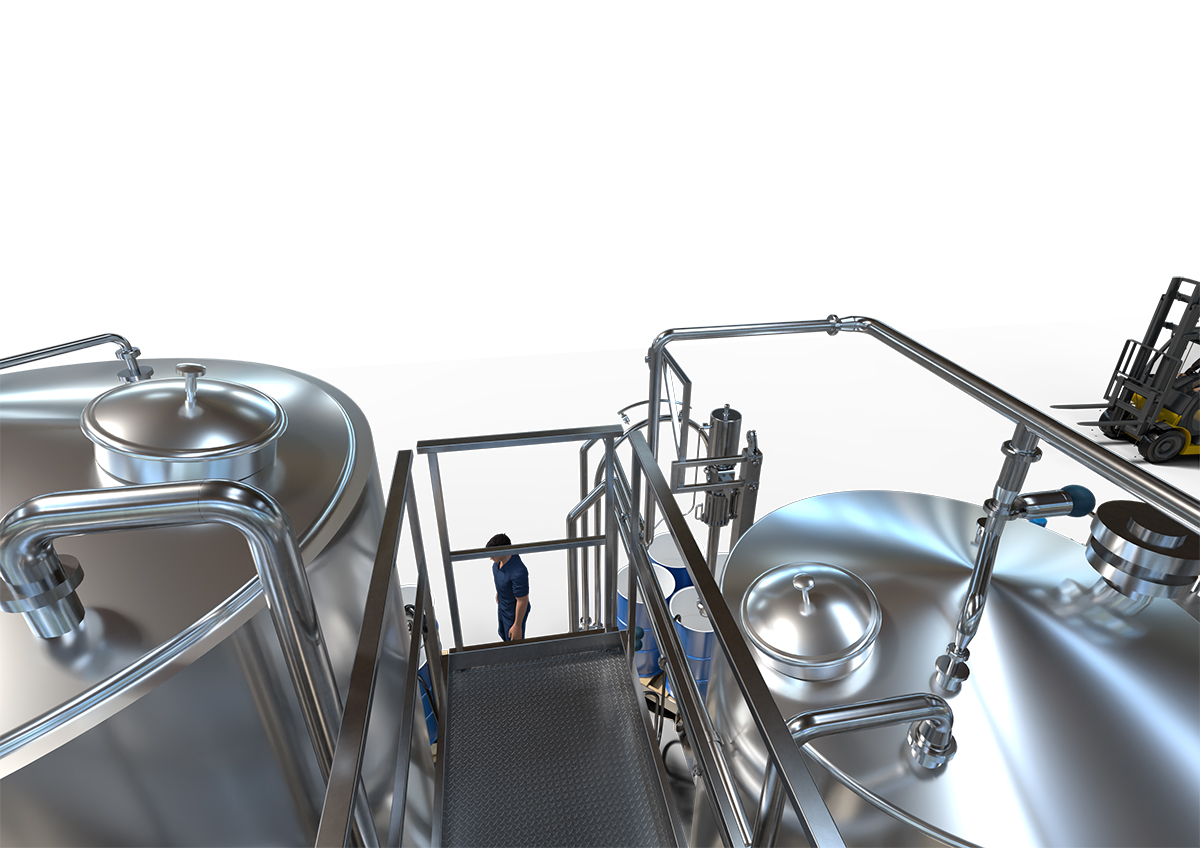

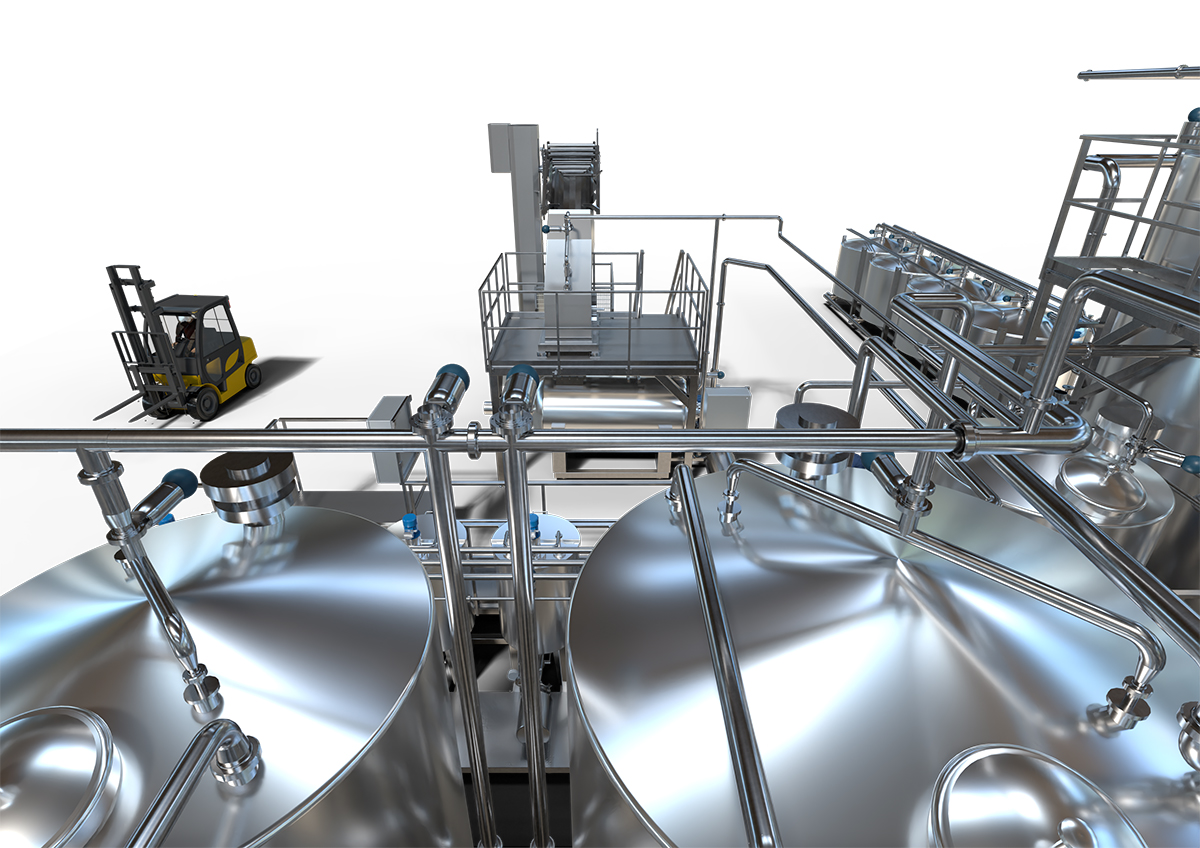

Equipment & lines for the processing of

formulated products

formulated products

Thanks to the big international producers that have entrusted us with their projects, we have created several applications for the processing of formulated products, obtaining a unique know-how.

These plants are the most complex ones realized in the food industry because, in addition to the process itself, accurate dosing and control of the ingredientsis required.

These plants are the most complex ones realized in the food industry because, in addition to the process itself, accurate dosing and control of the ingredientsis required.

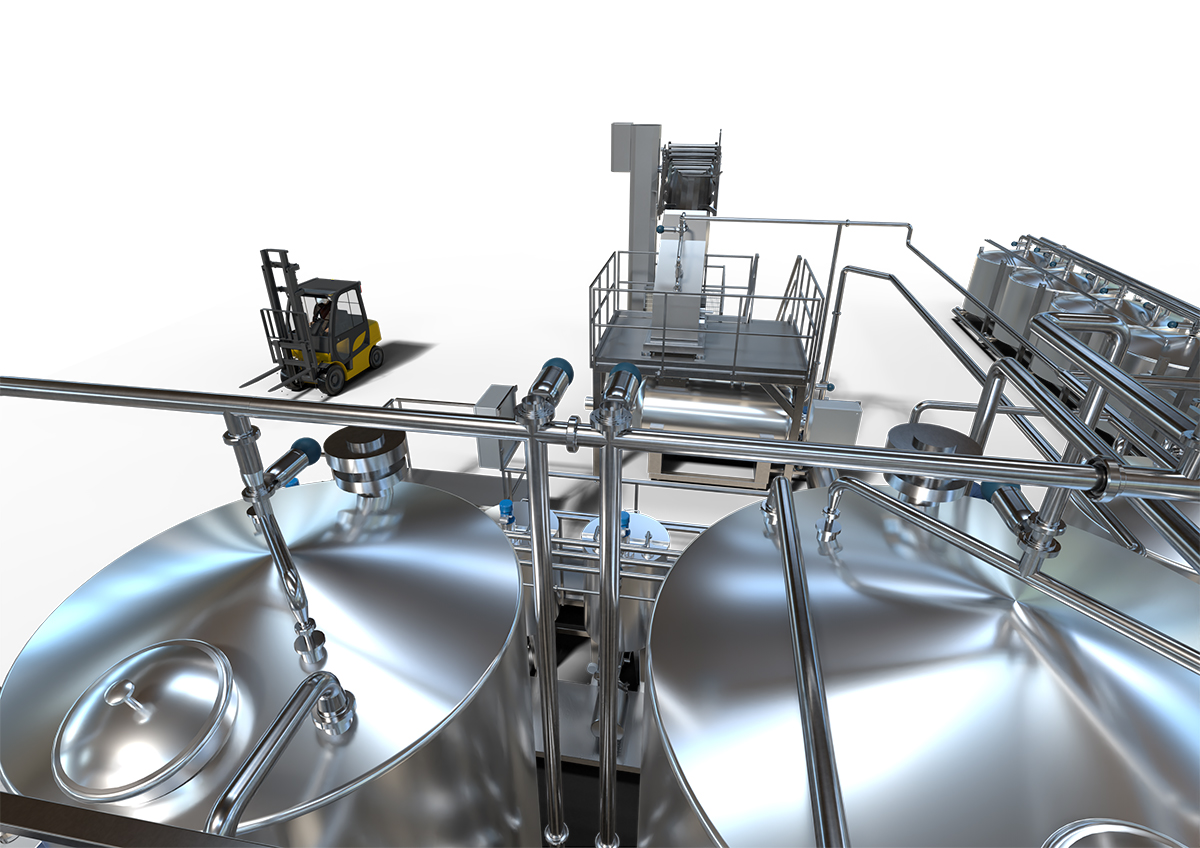

Our many years of know-how and design expertise covers a wide variety of formulated products.

Baby food

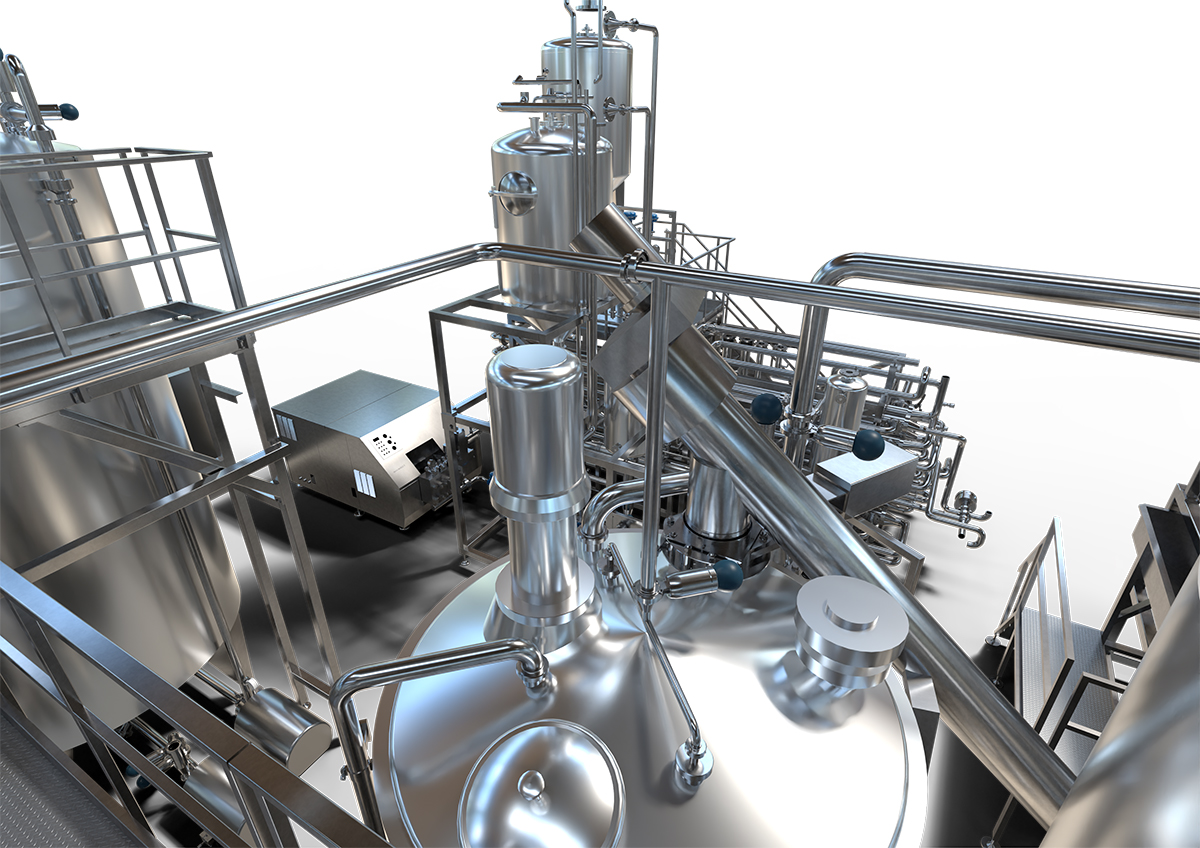

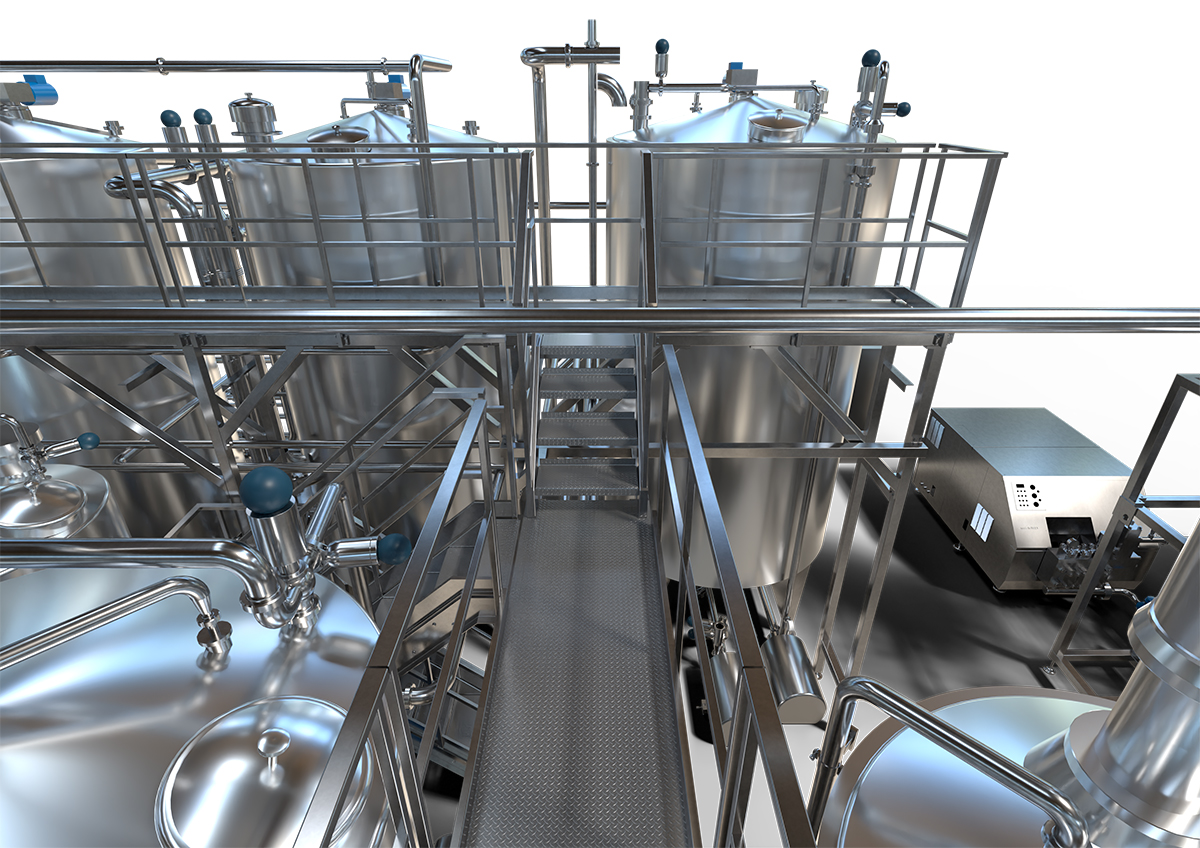

These are formulated fruit or vegetable products. Most often they are made with a base composed of several concentrates, mixed, and enriched with micro-ingredients, usually powders dissolved in a water solution. The obtained mix is treated with homogenizing pumps.

Juices and nectars

Products based on concentrates, with the addition of syrup and various types of sugar, along with other ingredients in powder form - first dissolved in a water solution -, and liquid (acids, flavorings, vitamins).

For large productions, syrup is often self-produced, starting with powdered sugar.

Finally, the product is often homogenized under high pressure.

Mayonnaise

Product obtained from a stable emulsion of vegetable oil in a water base containing egg, often flavored with vinegar, lemon, or spices. From a technological point of view, the most interesting mayonnaises are those with solids in suspension.

Tomato-based sauces

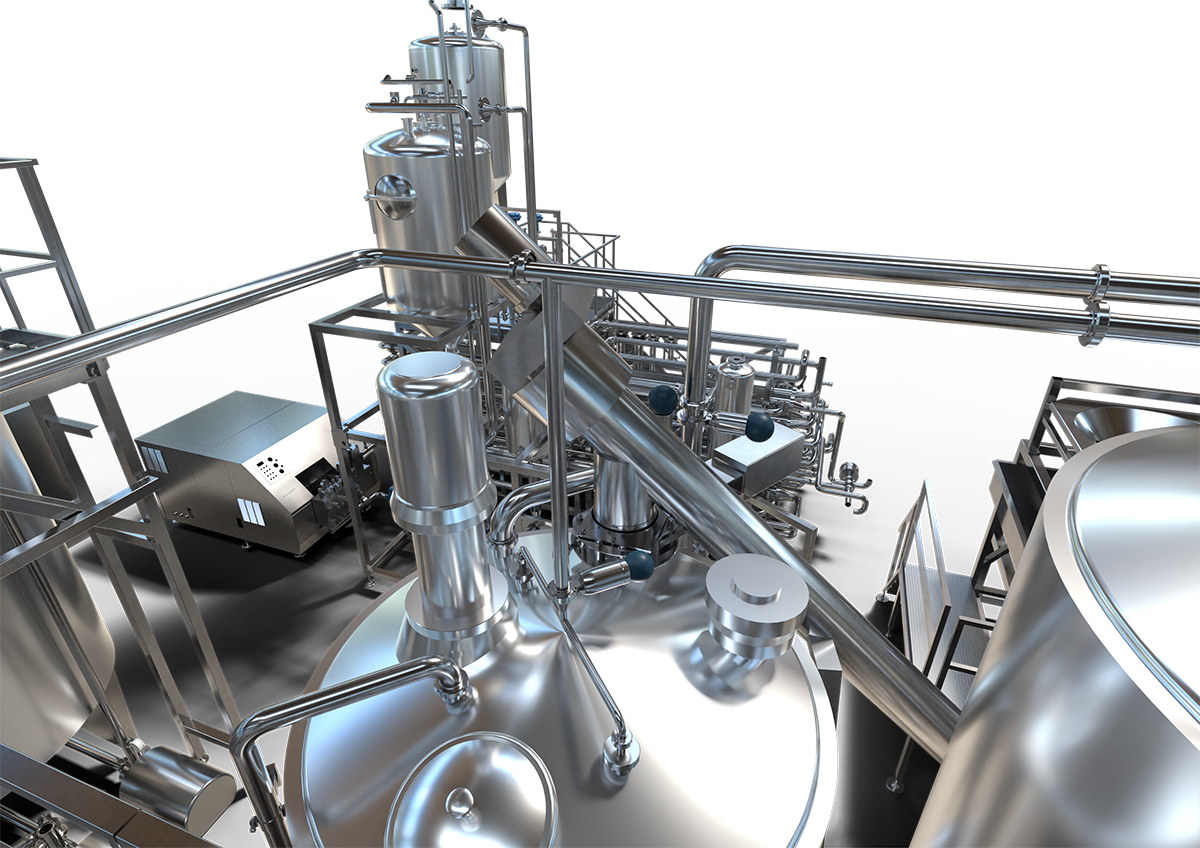

Such products sometimes require a “soffritto” base, a base of a lightly fried mixture of chopped vegetables. We have designed machines capable of making a partial change of the recipe, so that the soffritto can be prepared in the same machine in which the preparation of the complete recipe takes place.

The recipe includes a tomato base, made with different types of semi-finished products (a mix of puree and concentrate), with the addition of other ingredients such as vegetables, powders, and meat.

White sauces

Milk or cheese products. Considering the delicacy of the product, it is fundamental to know the type of treatment to be used from a thermal point of view. There are different types of white sauces, some homogenized with recirculating pumps, others with high pressure.

Ketchup

Ketchup is made from a base of tomato paste, with the addition of syrup, vinegar, flavorings, and other secondary ingredients. The product is often homogenized under high pressure.

Pesto and creams

In case of pesto sauces and creams, the use of a cutter is indispensable. Products treated with homogenizing pumps cannot be considered as such because the process does not allow the obtaining of a real and proper pesto, but a cream.

Heat treatment must also be skillfully used to prevent oily liquids from surfacing during the subsequent filling phase.

Semi-finished products

By semi-finished products we mean all categories of products that require formulation and are used as a base for other products. Some examples are ice cream bases, cocktail mixes, pastry creams, and similar products

Jams and marmalades

Efficient technologies transform fruit into semi-solid finished products, including jams and marmalades. We have designed the machines to minimize raw material waste, improving the yield and organoleptic qualities of the product.

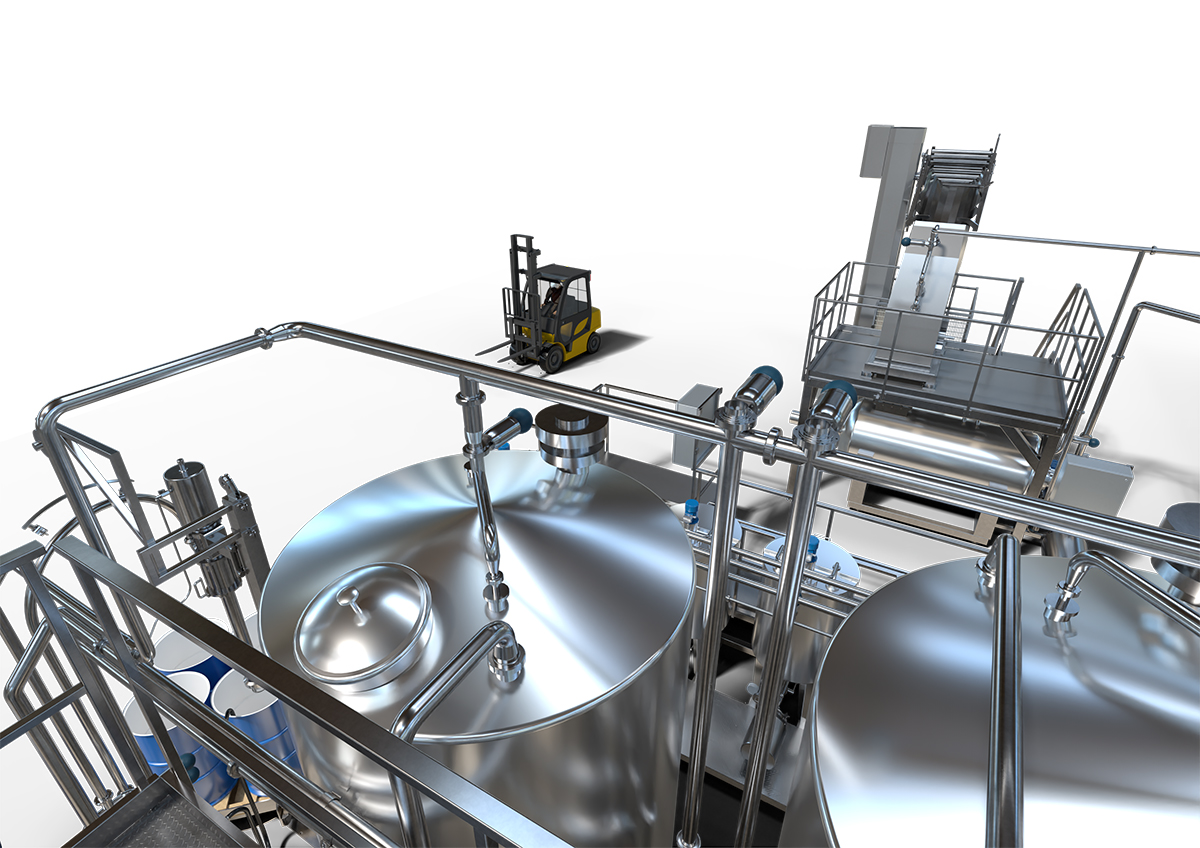

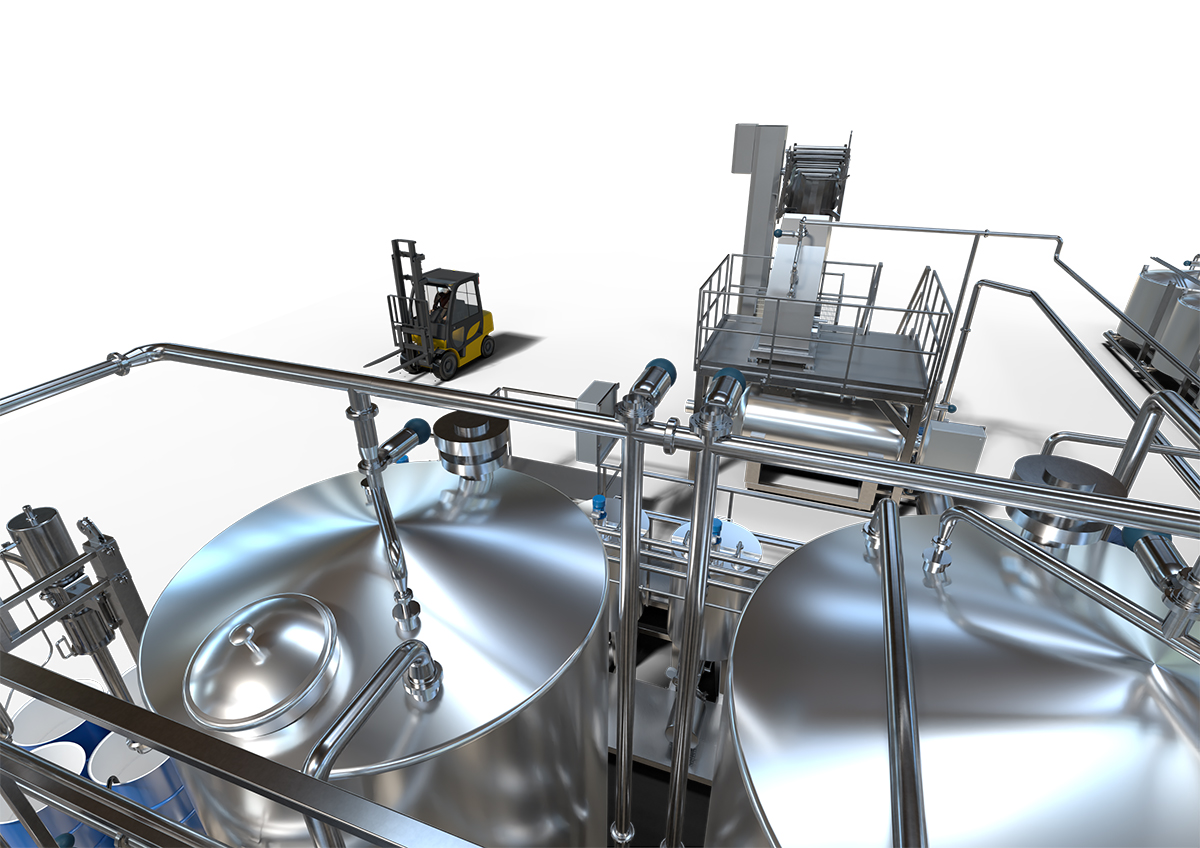

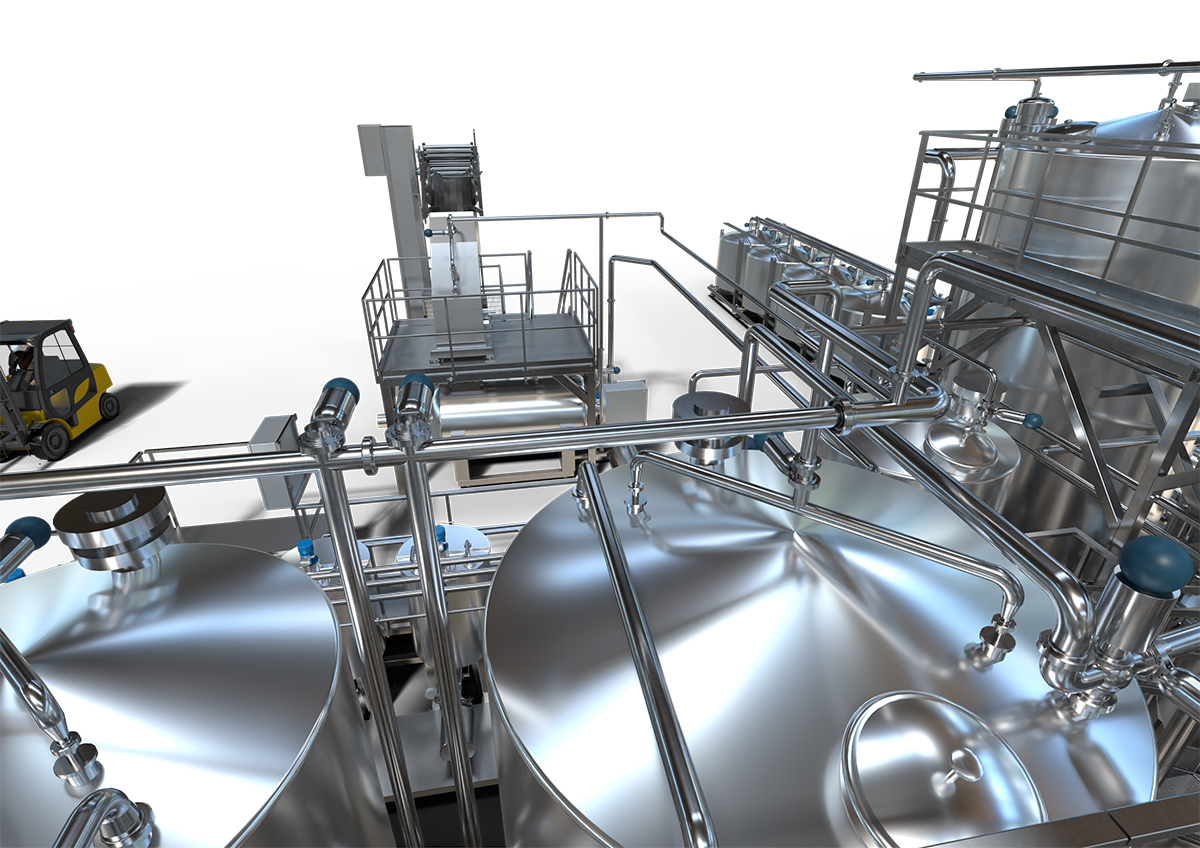

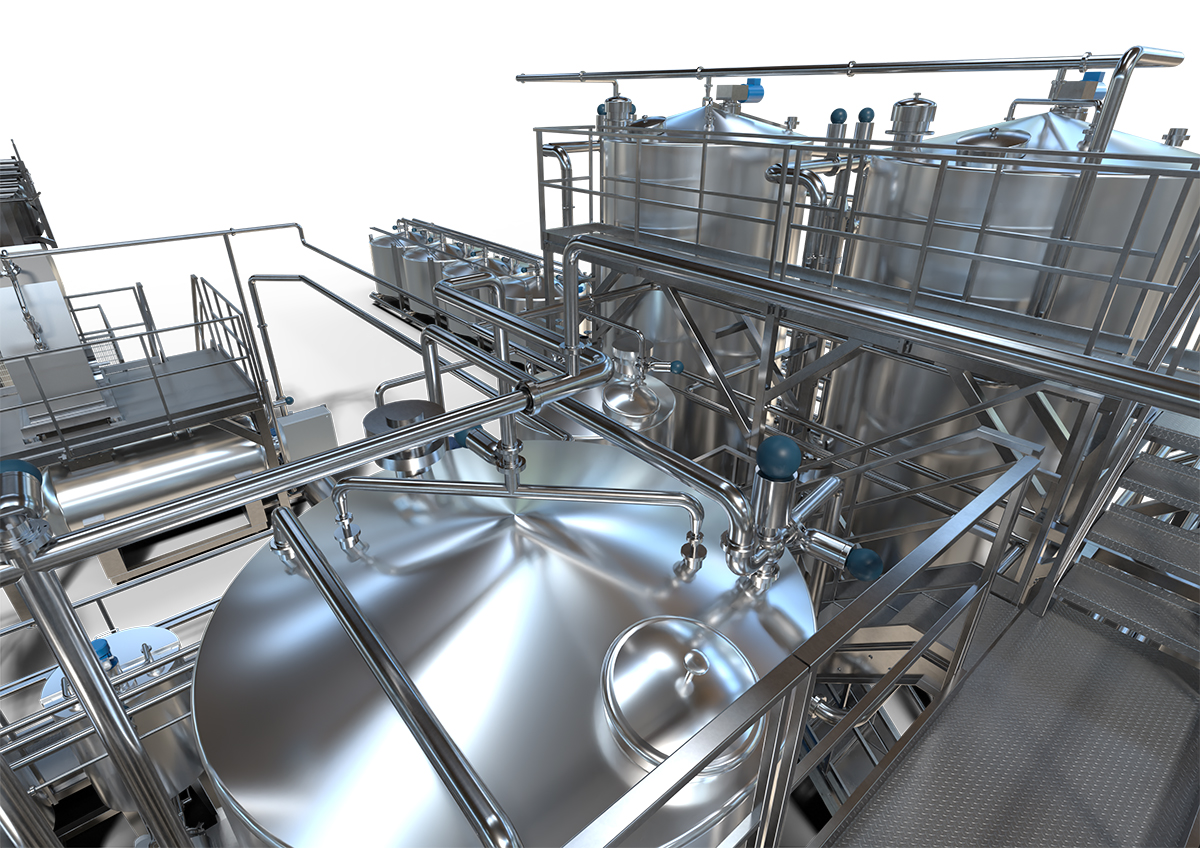

What is the strength of our processing lines for formulated products?

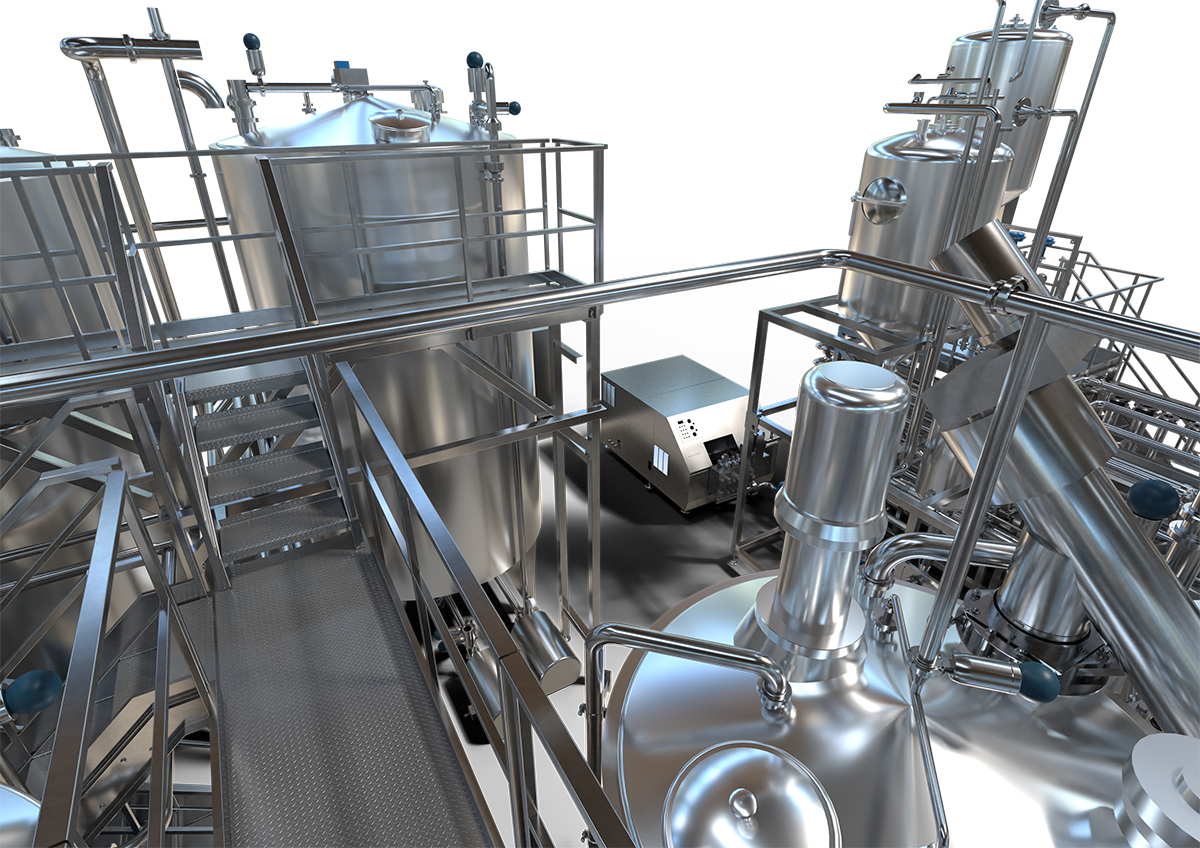

- High productivity with low residues at the end of production, with automatic control by the software.

- Rapid changeover of production: The possibility of sectioning the washings of the plant, with the aim of compressing and overlapping production and washing times.

- FDA certification for components and systems.

- Plants capable of making very different products with the use of the same machinery, for example, red sauces, mayonnaises, creams, and ketchup with the same plant.

- 100% automated process control and the possibility of raw material verification by bar code.

- Storage of history and staff interventions

- Multiple levels of passwords to allow differentiated operator, manager, and manufacturer access.

Interested in processing lines for formulated products?

Tell us about your project: we'll help you to achieve your goals.